Energy saving 20%| Space saving 50%|maintenance saving 40%|Improve efficiency 20%

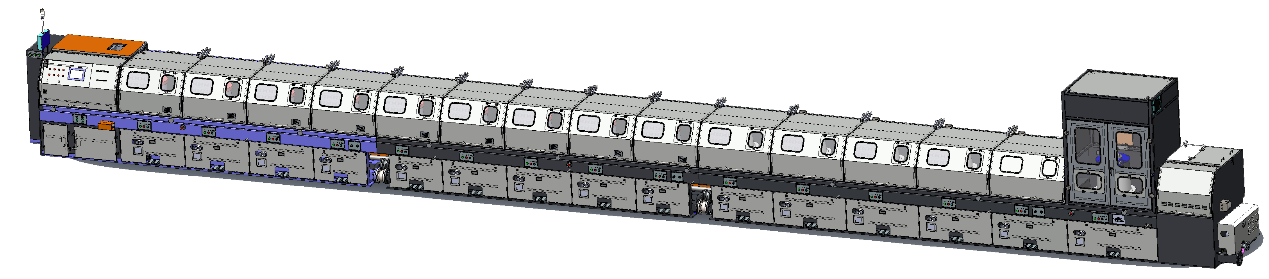

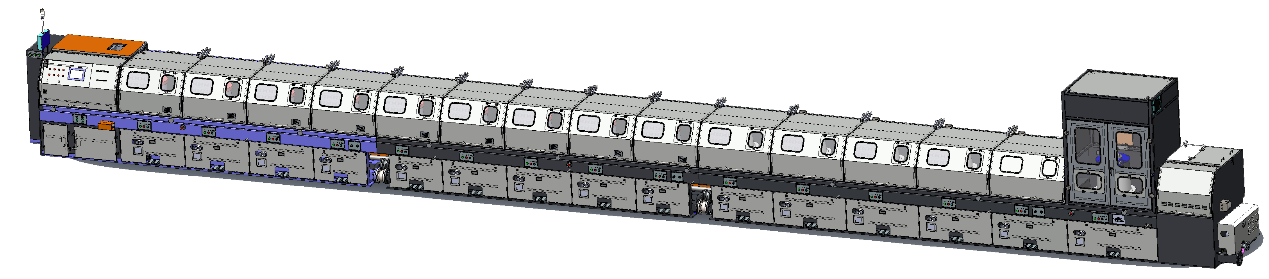

Product Introduction

Servo Direct Drive Technology (SDT) wire drawing machine is the * one to achieve the connection between motor and block *, which has merits in energy consumption, efficiency and maintenance, replacing parts of gearbox, belt and brake. It has a symmetrical and integrated design to save energy by 20%, space by 50%, maintenance by 40% and improve efficiency 20%. Such a machine has been applied widely in high, medium and low carbon wire, steel cord wire, bead wire, steel rope, welding wire, galvanized wire, PC strand, spring wire, stainless steel wire, golden steel busbar and so on.

Product Advantage

1、The host is a pure direct drive, no reducer, no belt, no mechanical brakes, high efficiency and energy saving, reducing land occupation and reducing maintenance costs.

2、Motor stator protection degree is IP65, guarantee motor is safe and reliable. Install temperature detector inside motor.

3、The wire drawing machine, electrical cabinet and control panel is integrated, and using same design standard.

4、In the shaft of driving, install temperature detector on bearing of upside and downside.

5、With coolant tank for motor and motor driver, install coolant circulation pump, temperature detector and liquid level detector.

6、With cooling water pump, frequency conversion control, to keep same cooling water pressure and flow on every block.

7、Temperature detection of whole machine inlet water and motor cooling water.

8、Capstan surface is tungsten carbide coated, capstan lifespan: ≥ 3 years. Inner water bush of capstan is made by Aluminium Alloy.

9、Customer can choice mixing die box, rotating die box, pressure die box.

10、With IC card manage function, management of personnel, production, maintenance and authority.

11、No wire broken when emergent stop machine.

12、With RJ45, can be used for customer to collect machine running date.

13、With LED display, to show current speed and ratio of wire on spool.

14、With intelligent power meter, to check quality of power supply, and meter power consumption of machine.

15、The whole machine equipped with power cable and control cable, customer just need supply power to electrical cabinet.

16、The after-service, will change parts, and not repair parts.

17、Optional: dust collection system, can clean dust in air and clean dust on drawing bench.

18、Optional: diameter detector laser type, can check wire diameter in real time, and make alarm when wire diameter is over range.

19、Optional: internet module, could-based IOT system, then can visit machine from mobile phone or PC to check running data, manage control system.

Product Parameter

|

Specification(block diameter)/mm

|

200

|

300

|

350

|

400

|

450

|

500

|

560

|

600

|

700

|

800

|

900

|

1200

|

|

Inlet strength/MPa

|

≤1350

|

|

Numbers of block

|

≤16

|

≤16

|

≤16

|

≤16

|

≤16

|

≤16

|

≤16

|

≤16

|

≤16

|

≤16

|

≤16

|

≤16

|

|

Maximum inlet diameter/mm

|

2.2

|

2.8

|

3.5

|

4.2

|

5

|

5.5

|

6.5

|

8

|

10

|

12

|

14

|

16

|

|

Minimum outlet diameter/mm

|

0.25

|

0.5

|

0.6

|

0.75

|

1

|

1.2

|

1.4

|

1.6

|

2.2

|

2.5

|

3

|

4

|

|

High drawing speed (m/s)

|

20

|

20

|

20

|

25

|

30

|

30

|

20

|

16

|

12

|

12

|

10

|

10

|

|

Motor power (kw)

|

2.2~5.5

|

5.5~7.5

|

5.5~11

|

11~15

|

11~22

|

15~30

|

22~45

|

30~55

|

45~75

|

55~90

|

75~110

|

90~132

|

|

Transmission system

|

Servo Motor Derict Dirve

|

|

Speed adjusting method

|

AC Servo Drives

|

|

Control method

|

Sharing DC Busbar Control System

|

|

Pay-off method

|

Spooler pay-off,High frame pay-off ,Horizontal pay-off,Duckbill pay-off,can pay-off without stop working

|

|

Take-up method

|

Spooler take-up,Coiler take-up,Inverted pay-off,can take-up without stop working

|

|

Main function

|

Can realize automatic stoping when broken wire or messy wire,each unit is equipped with independent protective cover,

monitoring process parameters and fault parameters

|

|

Suitable drawing materials

|

Steel wire(high,middle,low carbon steel wire,stainless steel wire,prestressed steel wire,bead wire,hose wire,spring wire,steel cord,etc.)

welding wire(GMAW,SAW,FCAW,etc.)alloy wire and various metal materials

|

Three-dimensional Display