Energy saving 20%| Space saving 50%|maintenance saving 40%|Improve efficiency 20%

Product Introduction

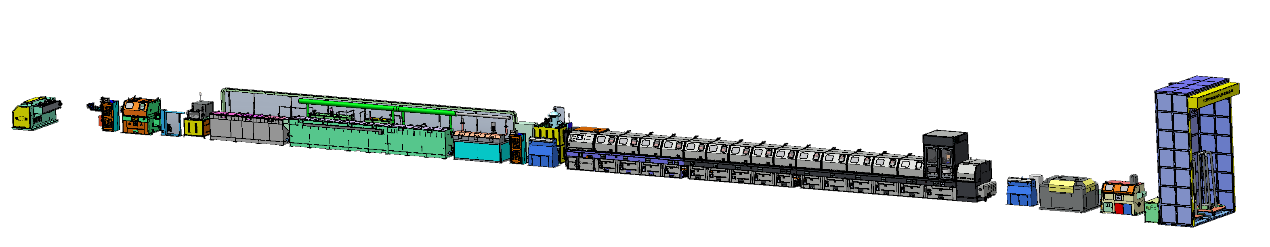

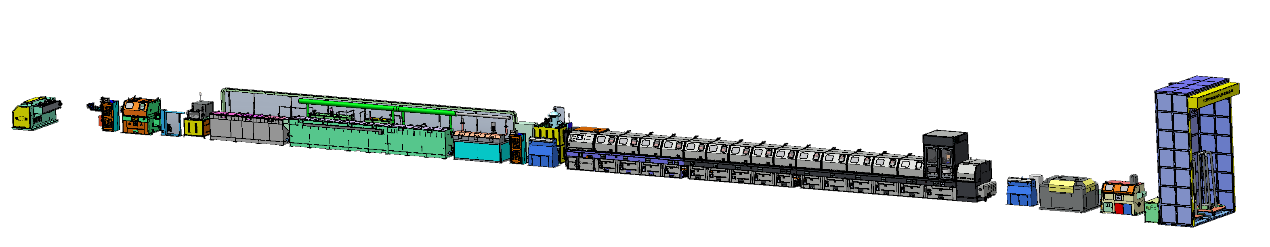

Integrating pretreatment, wire drawing machine, copper coating device and take-up. The design speed is 30 m/s, and the length of the whole line is 70 m. The wire drawing machine part still adopts servo direct drive type, motor direct drive capstan. Cancel the reducer, pulley, brake system, energy saving, high efficiency and low maintenance. The symmetrical design of the fuselage, the integration of electronic control and equipment, is committed to the goal of saving 20% energy, occupying 50% , 40% of maintenance and improving efficiency by 20%. Gas shielded welding wire copper coating integrated production line is widely used in the field of welding materials, such as gas welding wire, submerged arc welding wire, flux cored welding wire, aluminum welding wire, stainless steel welding wire and welding rod, etc.

Product Advantage

1.Innovated MIG Wire Drawing & Copper Coating Line

2.Highly efficient straight in electrical-chemical copper coating process

3.With rotating pressure die, suitable for highly speed drawing

4.Full automatic dosing system, reach concentration requested automatically

5.Fully automatic adding & discharge system, according to analysis

6.Integrated degrease device and highly pressure hot water washing device

7.Integrated pickling device and straight in electrical-chemical copper coating device

8.Full digit control power of pickling and coating accurately, copper layer more stable

9.Five high pressure and neutral water washing, unti-rust much better

10.Five high pressure and neutral water washing, unti-rust much better

11.Lubricant by oil in polishing block, with heating and cooling system for lubricant oil

Product Parameter

|

Specification(block diameter)/mm

|

200

|

300

|

350

|

400

|

450

|

500

|

560

|

600

|

700

|

800

|

900

|

1200

|

|

Inlet strength/MPa

|

≤1350

|

|

Numbers of block

|

≤16

|

≤16

|

≤16

|

≤16

|

≤16

|

≤16

|

≤16

|

≤16

|

≤16

|

≤16

|

≤16

|

≤16

|

|

Maximum inlet diameter/mm

|

2.2

|

2.8

|

3.5

|

4.2

|

5

|

5.5

|

6.5

|

8

|

10

|

12

|

14

|

16

|

|

Minimum outlet diameter/mm

|

0.25

|

0.5

|

0.6

|

0.75

|

1

|

1.2

|

1.4

|

1.6

|

2.2

|

2.5

|

3

|

4

|

|

High drawing speed (m/s)

|

20

|

20

|

20

|

25

|

30

|

30

|

20

|

16

|

12

|

12

|

10

|

10

|

|

Motor power (kw)

|

2.2~5.5

|

5.5~7.5

|

5.5~11

|

11~15

|

11~22

|

15~30

|

22~45

|

30~55

|

45~75

|

55~90

|

75~110

|

90~132

|

|

Transmission system

|

Servo Motor Derict Dirve

|

|

Speed adjusting method

|

AC Servo Drives

|

|

Control method

|

Sharing DC Busbar Control System

|

|

Pay-off method

|

Spooler pay-off,High frame pay-off ,Horizontal pay-off,Duckbill pay-off,can pay-off without stop working

|

|

Take-up method

|

Spooler take-up,Coiler take-up,Inverted pay-off,can take-up without stop working

|

|

Main function

|

Can realize automatic stoping when broken wire or messy wire,each unit is equipped with independent protective cover,

monitoring process parameters and fault parameters

|

|

Suitable drawing materials

|

GMAW,SAW,FCAW,aluminum welding wire,stainless steel wire,welding rod,etc.

|

Three-dimensional Display